Production Process

Producing quality plate manufacturings requires the organization and the management of an efficient production process, able to optimize to the top every step in order to compete with the other products on the market.

Keeping in its “DNA” the qualities of the traditional craftmanship, the production cycle is organized as such

The First Step consists of the CAD design, both in 2D and 3D. Here, the technical skill of the company emerges. As a matter of fact, the Customer can choose to entrust his project idea to Menzio’s design section or to transmit project data that will be examinated by the design section and about which will be given, if necessary, revisions and advices.

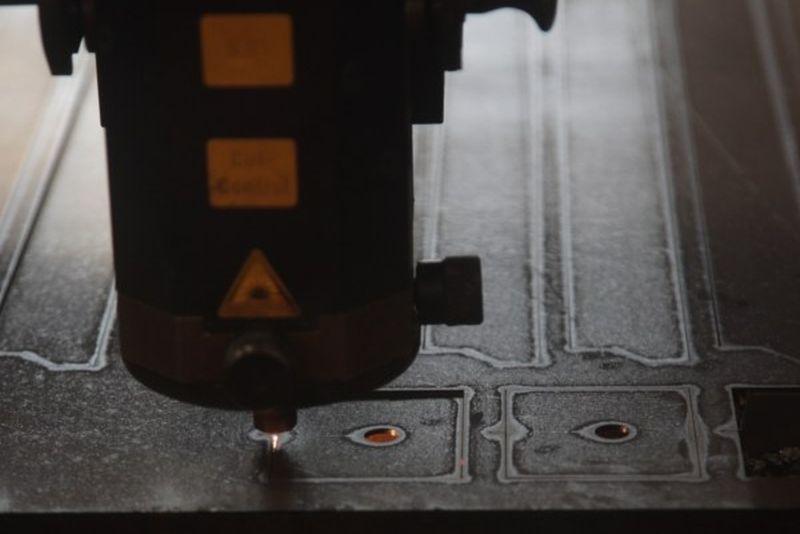

When design is complete, the second step consists of the project data transmission to the cutting machines via LAN. The avaiable systems are two: one operating with laser technology for plates 1 to 15 mm thick, the other is a plate stamper for plates 1 to 6mm thick. Then, the pieces made with the stamper are treated by a deburring machine for the edge finishing.

The third step consists of the passage to the bender machines that allows the single pieces to take the chosen shape.

The last step consists of the assembly for the construction of the planned manufacture, for example careenings suited for numeric control machines.

If required, Menzio company also has a painting department to deliver the product to the customer as asked (raw or coloured, as requested).

![_MG_2645 [800x600]](https://www.menziosrl.it/wp-content/uploads/2018/04/MG_2645-800x600.jpg)

![_MG_2624 [800x600]](https://www.menziosrl.it/wp-content/uploads/2018/04/MG_2624-800x600.jpg)

![_MG_2660 [800x600]](https://www.menziosrl.it/wp-content/uploads/2018/04/MG_2660-800x600.jpg)